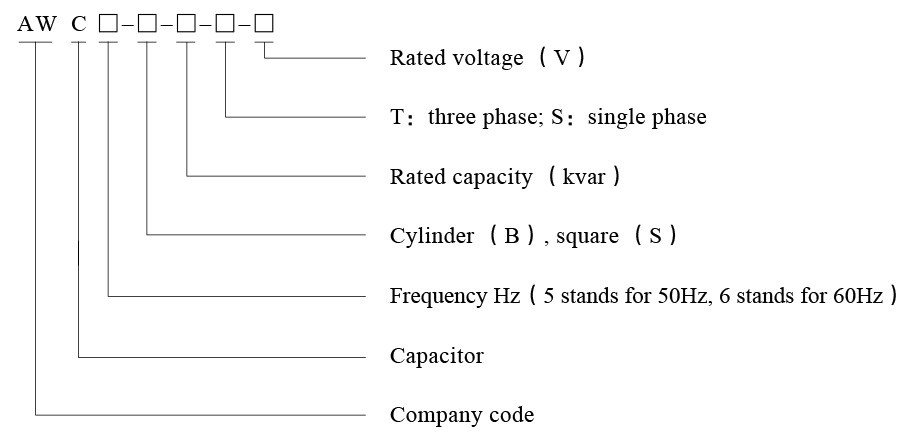

Mode coding

Product features

High quality metal film is adopted as medium. If the medium is damaged, metal electrode around the fault point volatilizes and disappears immediately to restore insulation, so that the capacitor recovers to normal condition and continue to operate, and self-recovery of insulation is realized.

Unique design, to reduce volume and weight; screw fixation, convenient and flexible, and maintenance time is reduced.

Metal shell packaging, internal medium contacts with external Al shell so that heat dissipation may be realized directly; high quality medium improves the capacity and ensures lower power losses, lower temperature rise and longer service life. Capacity fading is low, so that expenses for power consumption are reduced significantly.

1、Insulated protective cover is adopted, to protect capacitor terminal blocks and connecting wires. Discharge resistor and over-voltage protective devices are installed to ensure safety of power consumption and maintenance operations, and to prevent and isolate occurrence of disasters.

2、Every capacitor unit is configured with an over-pressure protector for reliable protection. Because capacitor breakdown may be caused by progressive damages or instantaneous breakdown, Andlite has designed a dedicated internal pressure protector to ensure that the capacitor will not burst under extreme conditions.

3、Over-pressure protector utilizes internal pressure caused by overheating of short-circuit current to disconnect terminal contacts when effective service life of the capacitor expires and the capacitor fails to recover automatically. When fault occurs, the contact will be disconnected due to pressure, to ensure that insulation of the shell is intact and prevent explosion or swelling of the capacitor.

4、Natural vermiculite is filled into the capacitor to prevent fire and explosion. At high temperatures, the vermiculite will dissolve automatically to isolate combustion source and oxygen, so that fault of the device will not spread and electrical safety of the capacitor is ensured.

5、By firm welding connection of internal protective devices to protect the capacitor against over-current, over-temperature and over-pressure, shell of square capacitor is made of high strength galvanized steel plate to ensure high level of safety.

Insulation fillers are adopted for packaging, to prevent oil leakage during application and avoid environmental pollution. This is a proprietary green product of Andlite.

Protectors are installed for individual capacitors. when the whole circuit or a single capacitor breaks down, the protector is activated immediately to disconnect the power source and prevent secondary accidents.