High voltage capacitors have inner-fuse and outer-fuse structures, indoor pattern and outdoor pattern, single phase and three phases. Multiple new technologies, including SAS-40E solution and M/DBT impregnant, are adopted for strict vacuum treatment and manufacturing. The new generation of high voltage capacitor products has the advantages of high electrical performances, low losses, no pollution and long service life.

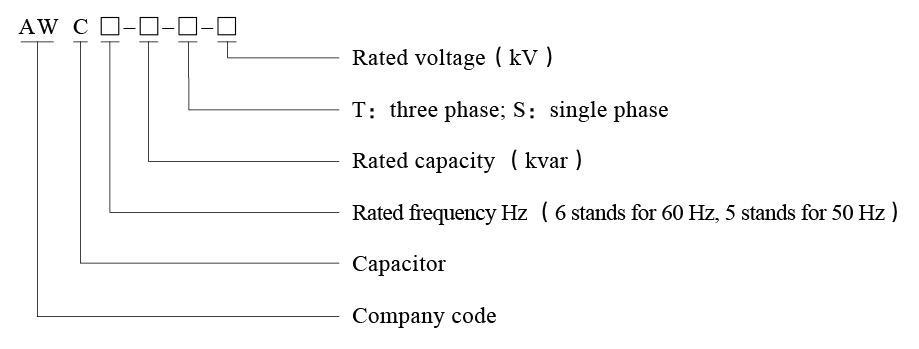

Mode coding

Technical specification

Service conditions

Special technical features of the products

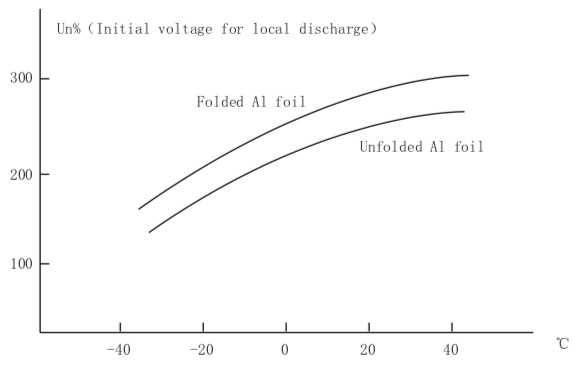

Because electric field at edge is rather high, electric corrosion may occur to aluminum foil edge of capacitors and early damage may be caused to the edge. Edge-fold process may improve local discharge performance by about 20%. As shown in the following figure:

Local discharge vs medium temperature

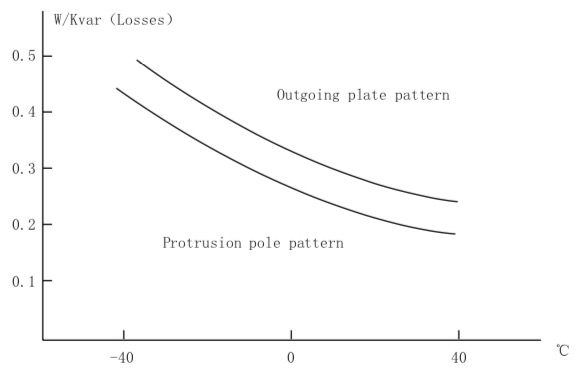

Resistance losses of pole plates may be eliminated essentially by protrusion design of pole plates. Transient over-current capacity is improved and reliability of large capacity capacitors are improved in particular. As shown in the following figure:

Losses vs temperature

Sufficient removal of gases in shells of capacitors, and enough impregnation of insulation impregnant are paramount to ensure quality of capacitors. Independent oil impregnant treatment system adopts single treatment for capacitor, with direct and reliable effects. Injection of impregnant is completed by an independent system, so better performances of vacuum treatment and impregnation for capacitor is ensured.

Novel and unique internal fuse with notch (by breakpoint design), provides better ampere-second features, and more reliable action.